Beverages Production System – Dash SaaS Add-On.Optimize and automate your beverage manufacturing process with the Beverages Production System – Dash SaaS Add-On. Designed for beverage producers and bottling units, this robust tool enables precise production planning, ingredient tracking, batch monitoring, inventory control, and quality assurance. Seamlessly integrated with Dash SaaS, this beverage production management system enhances productivity, reduces waste, and ensures consistent product quality from production to packaging.

Note: This is an addon for WorkDo Dash SaaS, not a standalone script.

WorkDo Dash SaaS - Open Source ERP with Multi-Workspace

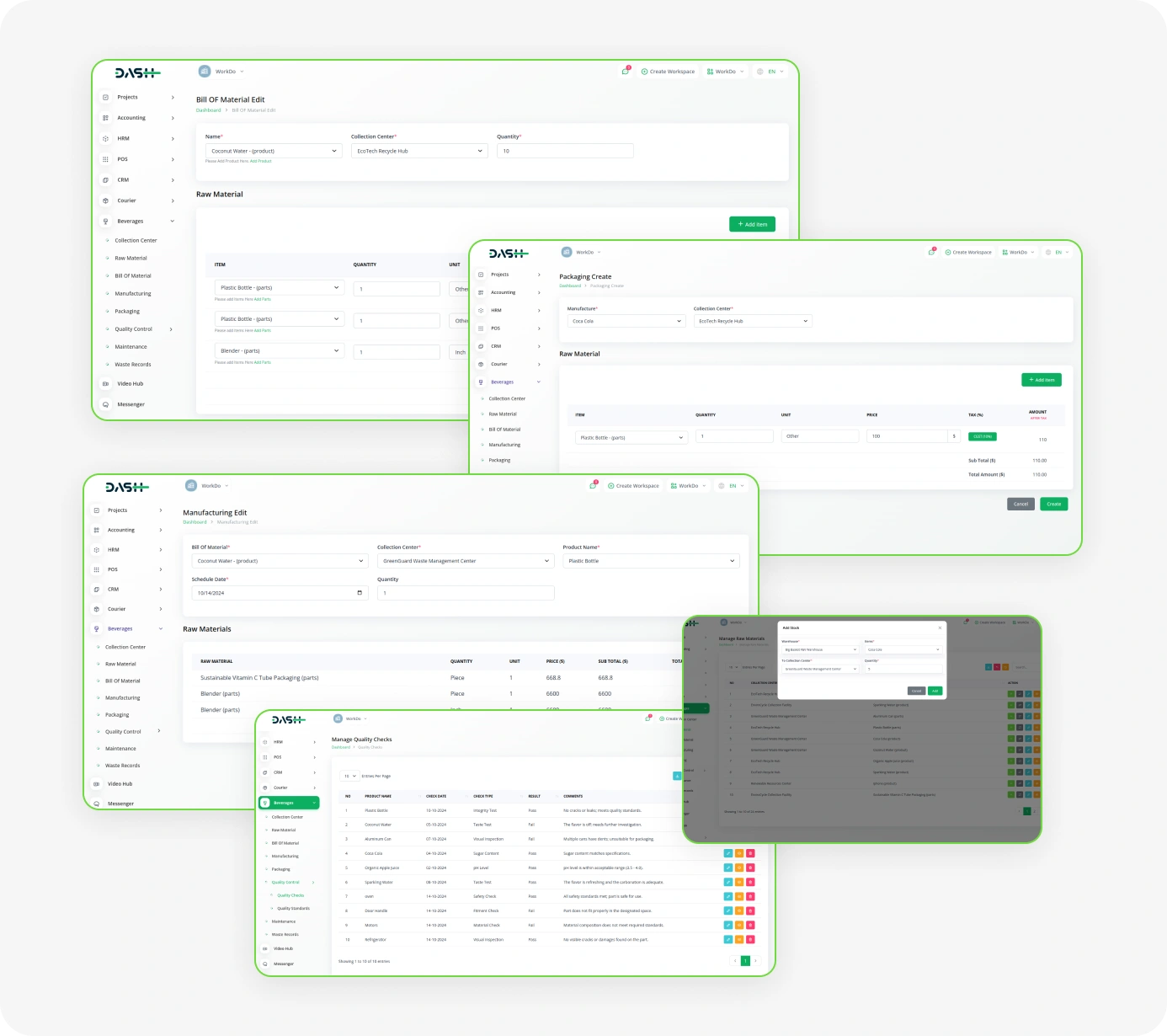

The Beverages Production System is a powerful and user-friendly platform designed to manage the entire beverage production workflow. From collecting raw materials at various centers, manufacturing and packaging finished goods, to conducting quality checks, managing equipment maintenance, and tracking waste, the system ensures efficiency and compliance at every step. Smart status-based controls, seamless stock movement, and comprehensive data tracking help streamline beverage production operations from start to finish.

Check here : Beverage Production System | A Step-by-Step Guide with Dash SaaS | Manage your Own Business

Beverages Production System

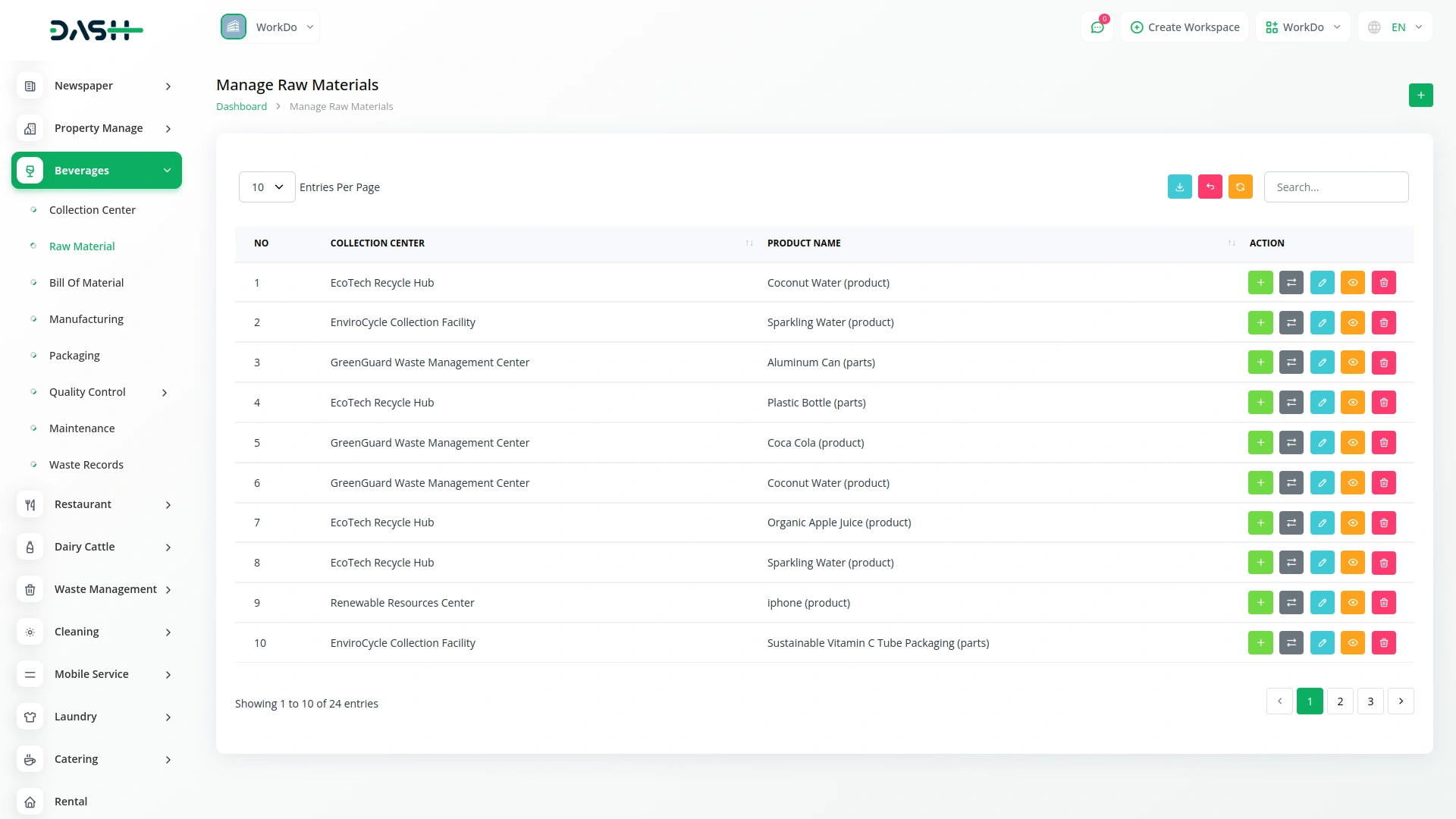

Raw Materials Control

Efficiently manage raw materials by selecting a collection center and then choosing the desired product or service items separately. Once an item is selected, the system auto-fills its name, description, tax, price, unit, and image to streamline input. You can set the raw material status (active/inactive) for availability control. Additionally, manage stock levels, move materials from one collection center to another, and perform key actions like viewing, editing, or deleting entries to maintain clean and accurate inventory records.

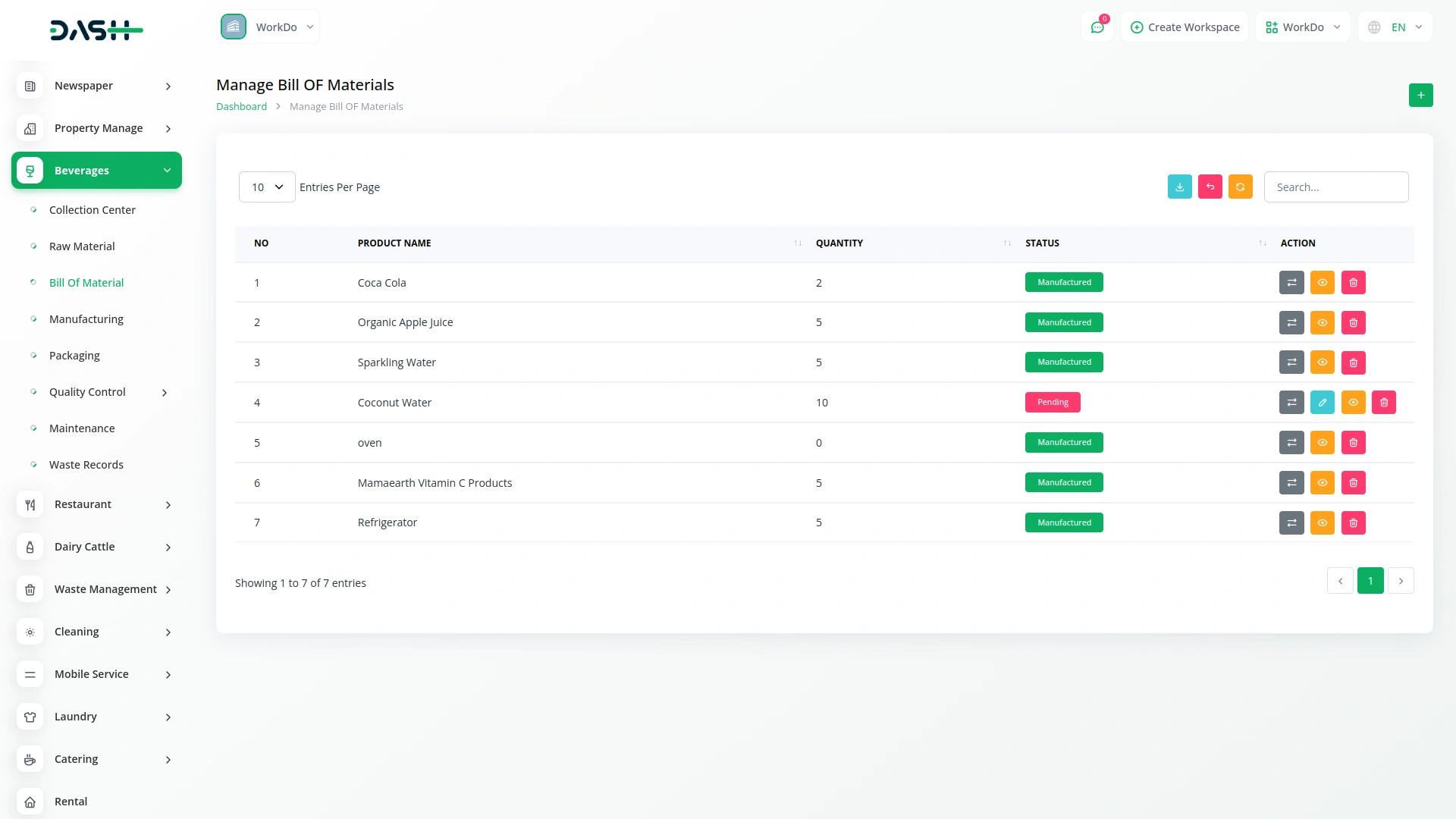

Bill of Materials Management

Manage your manufacturing resources efficiently by defining and organizing material requirements for production. This feature allows you to specify what quantity needs to be manufactured and the list of raw materials required, including their unit, quantity, price, and subtotal. The system also tracks the status of each bill (pending or manufactured) and assigns actions like move stock, view, edit, and delete for smooth operations. This ensures a well-planned and cost-effective manufacturing process.

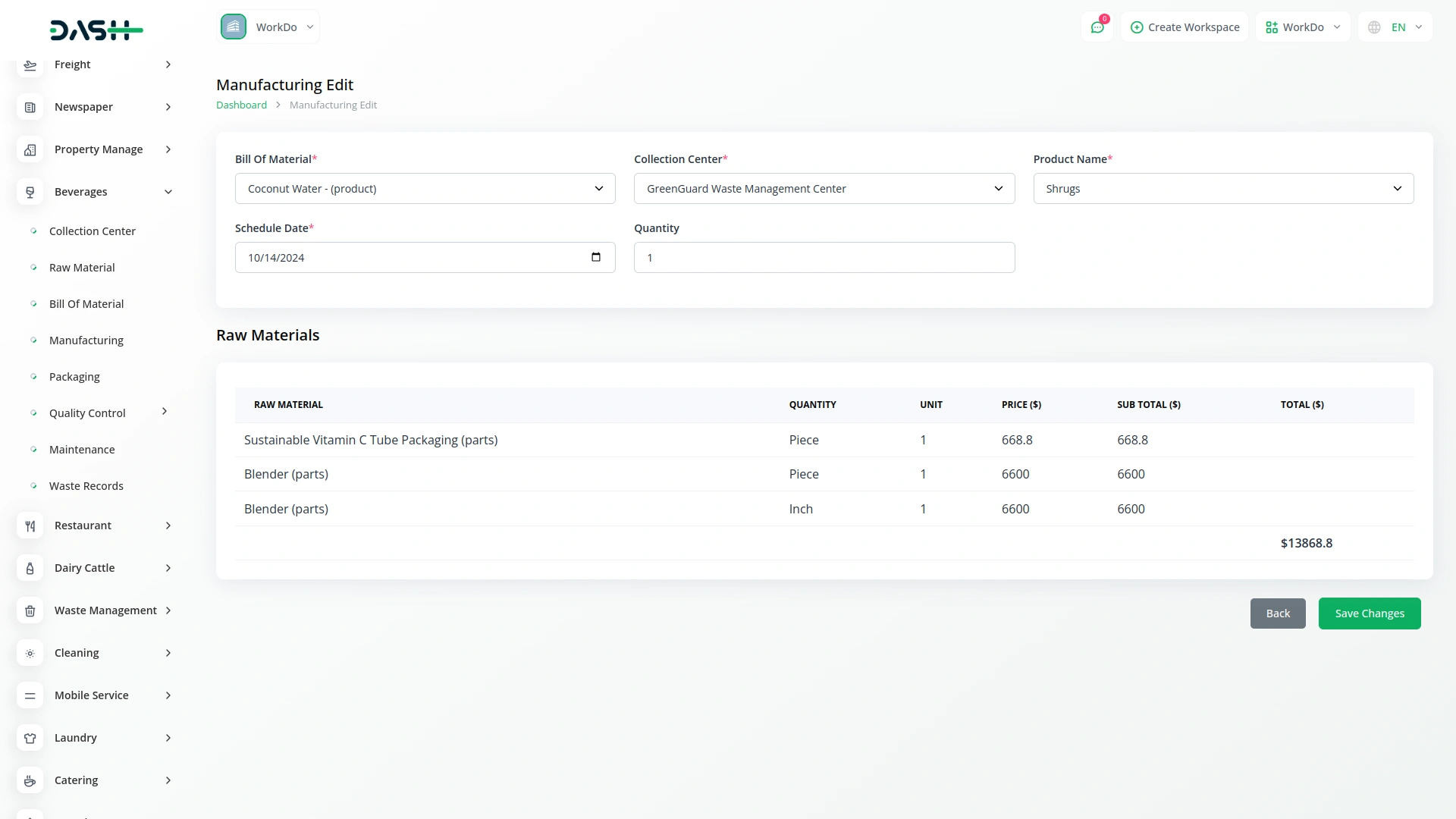

Manufacturing Order Creation

The Manufacturing Create Page simplifies the process of initiating and managing manufacturing orders. Users can select a Bill of Material, assign a Collection Center, and choose a Product/Service item for production. They can also set the Schedule Date and specify the Quantity to be produced. The status of a manufacturing order is initially set to Pending. Once the order is processed and the manufacturing is completed, the status is updated to Completed. Users can view and edit only pending orders, while completed orders are locked for editing. The system also provides an option to delete orders if necessary.

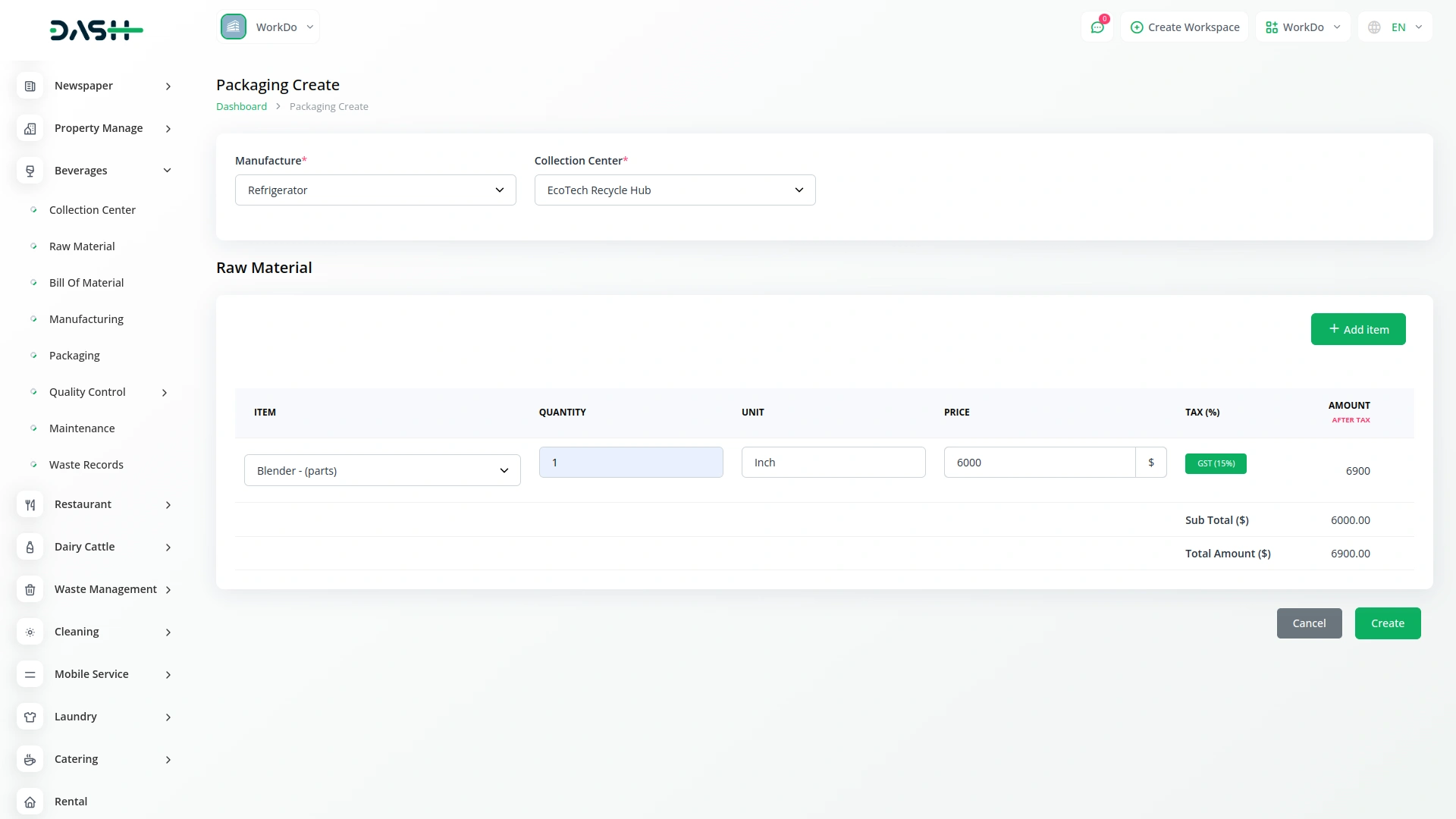

Packaging Process Overview

In the packaging, users can create new packaging records by selecting a completed manufacturing order and assigning it to a collection center. Based on the selected manufacturing, related raw material items are automatically listed with fields like quantity, unit, price, tax, and total amount. This step ensures that packaged products are accounted for correctly before distribution. Packaging status starts as "pending" by default and includes various actions for seamless stock handling and record management.

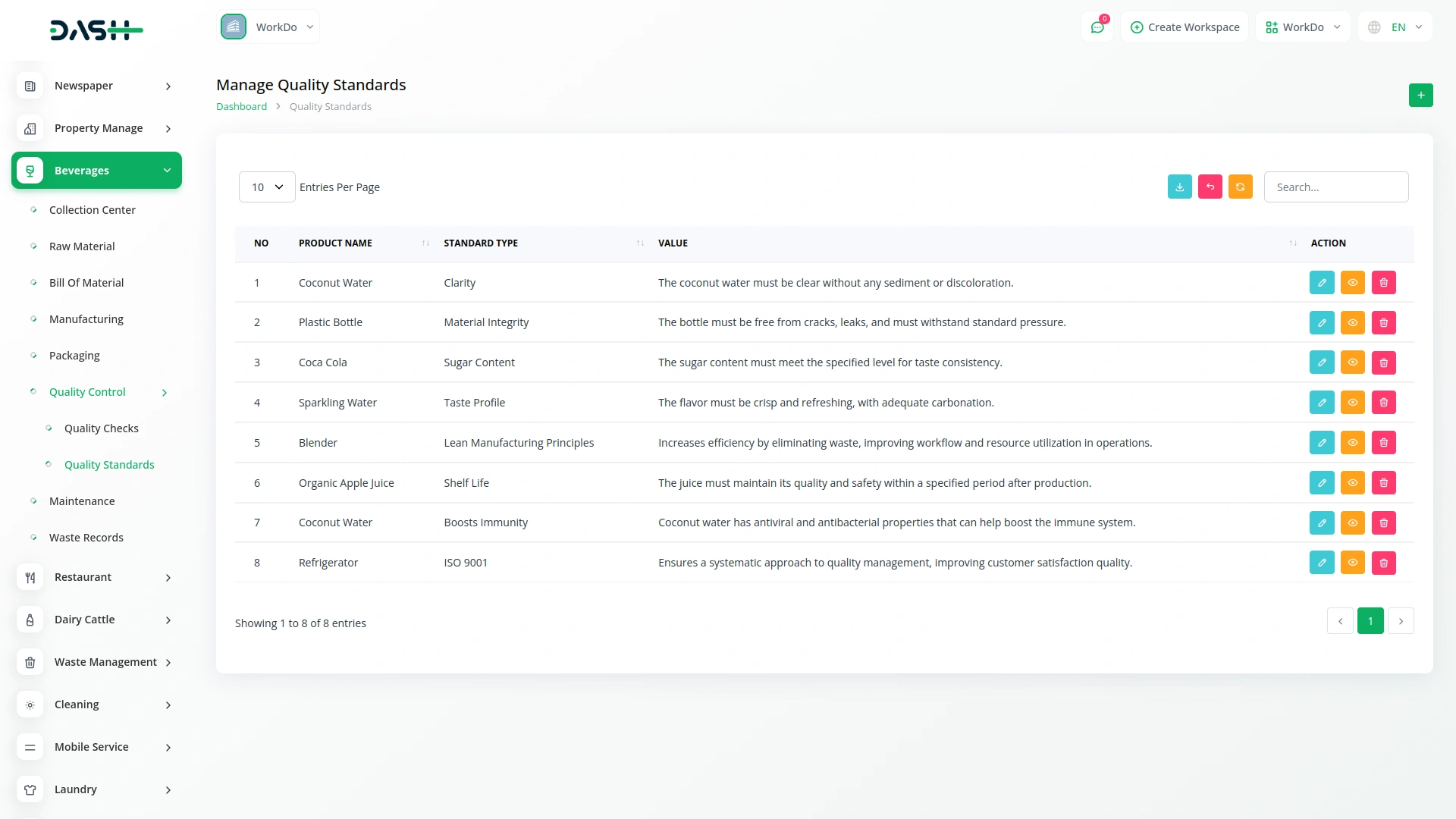

Quality Control & Checks

Ensure every product meets the expected standards with a built-in quality control process. The system allows you to define standard benchmarks for each product/service item, categorized by standard type and value. Once defined, you can perform regular quality checks, log results, and track outcomes with detailed comments. This helps maintain high product quality across all production batches.

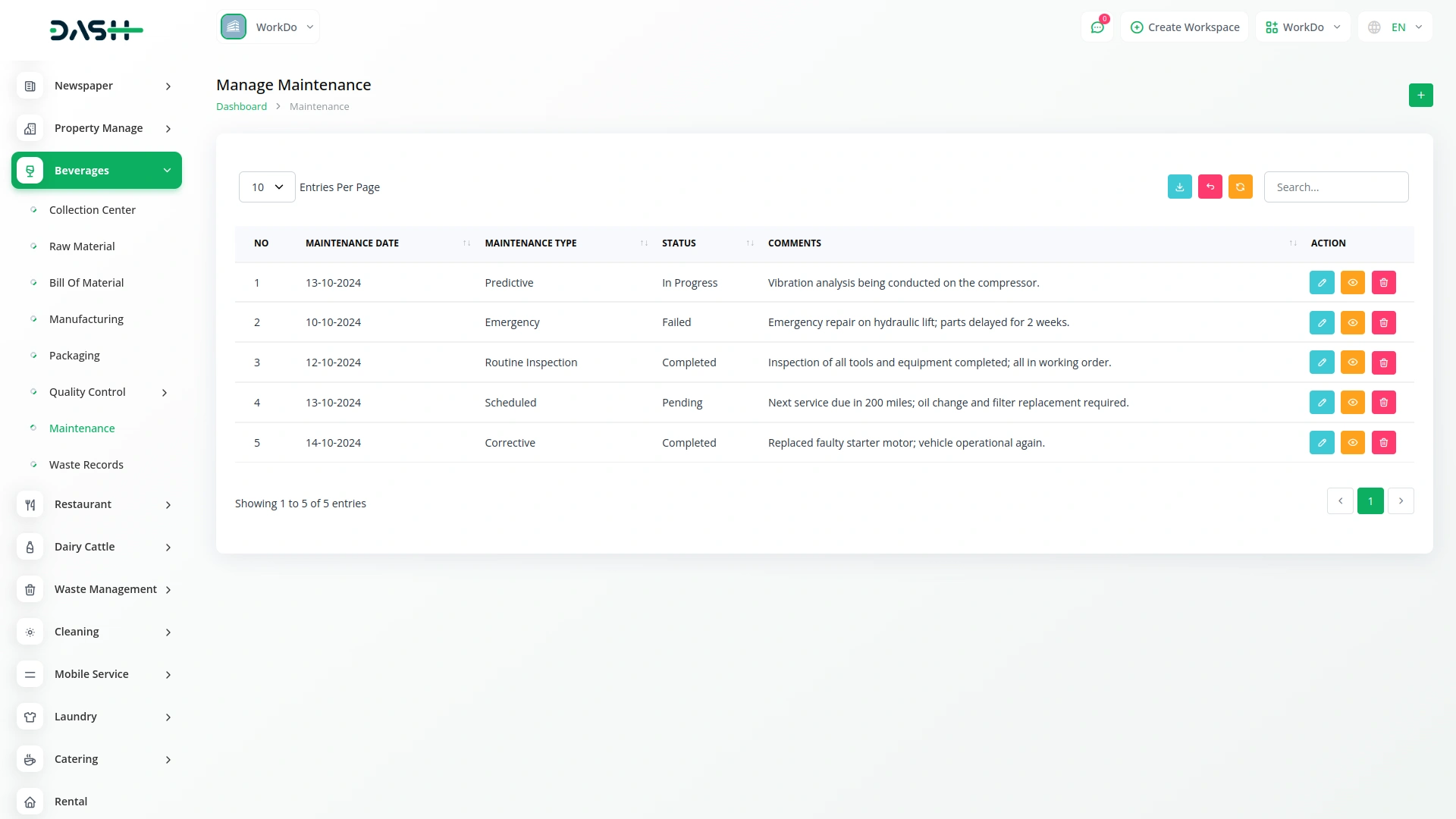

Maintenance Management

Stay on top of equipment upkeep with a dedicated maintenance tracking system. Record and monitor all maintenance activities with relevant details like the type of maintenance, scheduled date, current status, and technician comments. This ensures optimal performance of your manufacturing and packaging systems and reduces downtime.

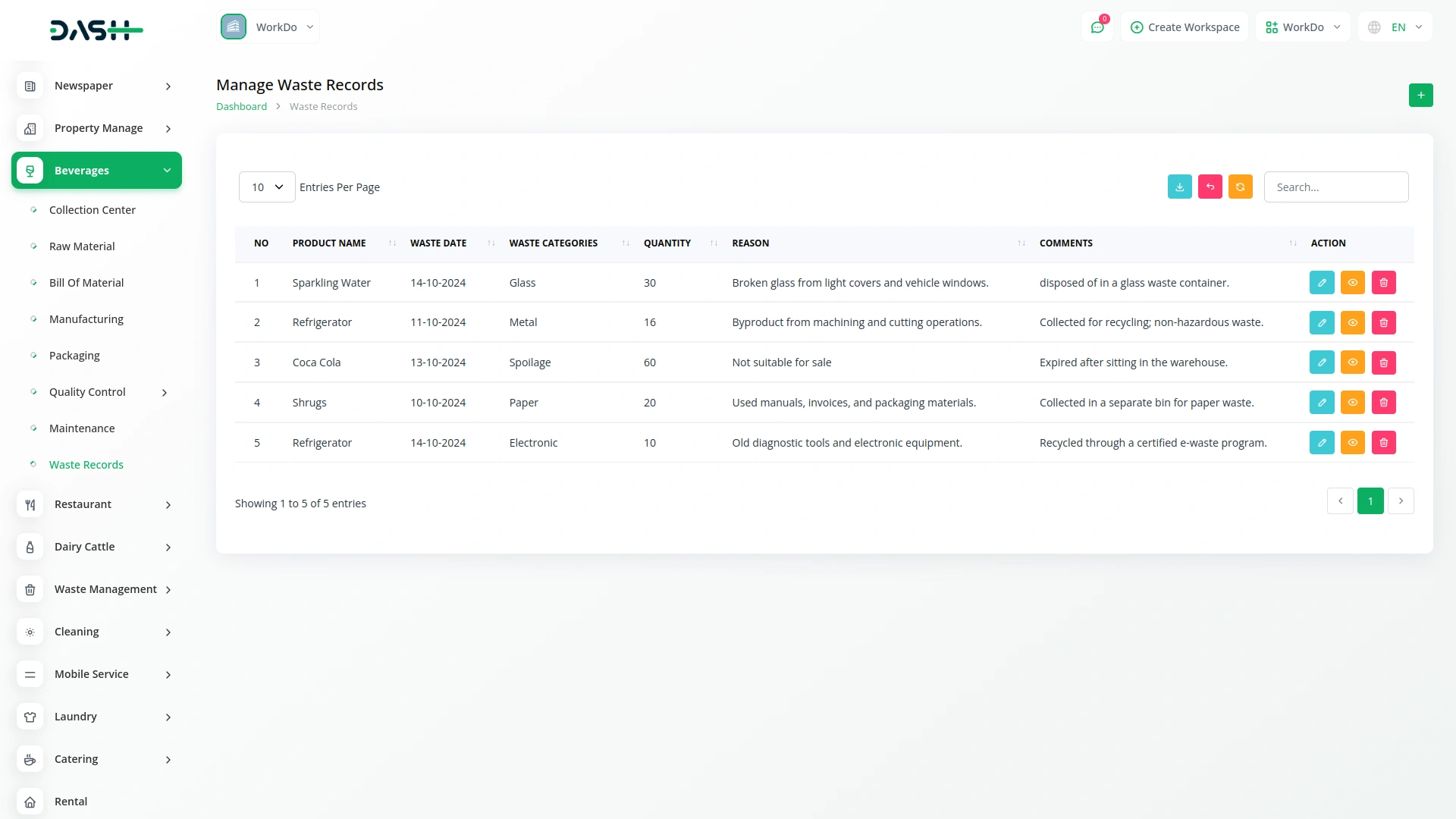

Waste Records

Effectively record and analyze material waste during the production cycle. This feature allows you to track waste entries by item, date, category, quantity, and reason, helping you identify process inefficiencies and minimize losses.

Check here : View WorkDo Dash SaaS Documentations

Check here : Explore WorkDo Dash SaaS User Manual

Check here : How to install Dash Add-On

Last update:

Jan 22, 2026 08:08 AM

Version:

v1.0

Category:

High Resolution:

YesSoftware Version:

Files Included:

Software FrameWork:

LaravelPublished:

Jul 23, 2025 09:48 PM